Factors Affecting Fiber Laser Cutting Efficiency

Fiber laser cutting machine is a precision processing machine that is widely used in many fields such as metal processing, industrial manufacturing, and automobile manufacturing. With the development of science and technology, laser cutting technology continues to improve, providing more precise and faster cutting results. However, the effectiveness of laser cutting is affected by a variety of factors, which will be described in detail in this article.

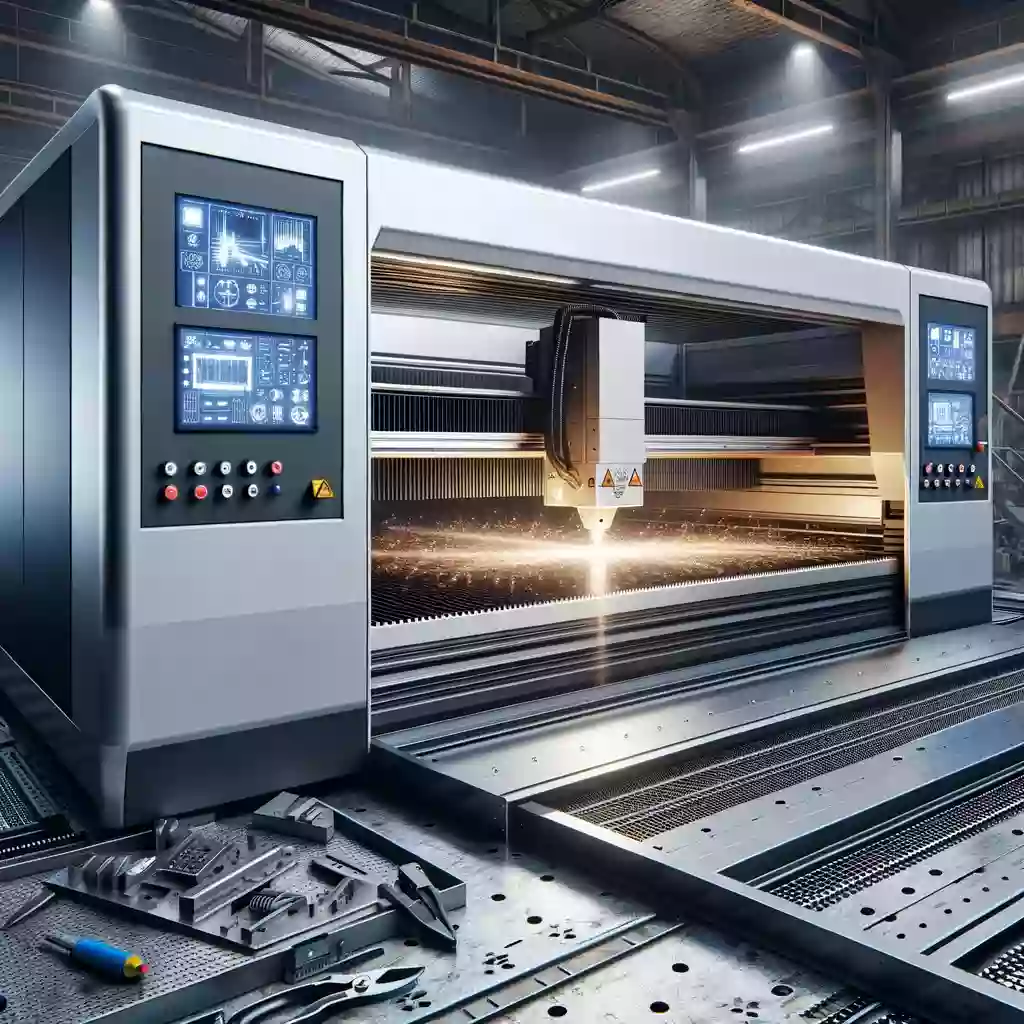

Ⅰ. Laser Cutting Principle

Laser cutting is a process in which a high-power laser is focused on the surface of the workpiece to be cut, causing it to melt or burn. It is then supplemented by cutting gas to blow away the slag. The cutting head moves on the surface of the workpiece to form a slit and separate the workpiece. .

Ⅱ.Laser Output Power

1.How laser output influence the performance

Laser output power directly affects the performance of the fiber laser cutter. Generally, as the plate thickness increases, the required laser power also increases. In cutting the same type of plate with the same thickness, the greater the laser output power, the faster the cutting speed, and the smoother the cutting section.

2.Subsidiary premise

However, after the output power is determined, the cutting speed must be consistent with the material material and thickness, so that the optimal cutting speed can be achieved. For good cutting effect, too fast or too slow speed will affect the laser cutting effect.

Ⅲ.Laser Output Mode

1.Single mode and multimode

The beam quality distribution form of the laser is divided into single mode and multimode. When the beam energy density has only one concentrated point, it is called single mode. When the beam energy density has two or more concentrated points, it is called multimode.

2.Comparisons between single mode and multimode

The fiber core of single-mode lasers is thinner and the beam quality is better than multi-mode. The fiber core of multi-mode lasers is thicker and the beam quality is worse than that of single-mode lasers. The energy distribution is more average than that of single-mode light spots. The three-dimensional image is an inverted cup. Judging from the steepness of the edge, the multi-mode one is much steeper than the single-mode one.

3.Advantages of single mode and multimode

The advantage of single mode is in thin plates, and the advantage of multimode is in thick plates. Single mode and multimode have no mutual comparison value. They are both configurations of fiber lasers.

Ⅳ. Cutting Speed

The cutting speed and laser power determine the cutting efficiency and quality of the material. Speeds that are too fast may result in incomplete cuts, while speeds that are too slow may result in overburning. A reasonable cutting speed should be adjusted according to the type and thickness of the material to achieve the best cutting effect.

Ⅴ. Focus Position

The focus position of the laser cutting head has a direct impact on the cutting quality. If the laser focus is aimed at the surface of the material, a more ideal cutting effect can be achieved. The shift in focus position will lead to reduced laser cutting efficiency, such as uneven incision width or rough cutting surface.

Ⅵ. Material Type and Thickness

1.Material type

Different materials have different abilities to absorb laser wavelengths, which directly affects the effect of laser cutting. For example, steel and aluminum have very different parameter settings when laser cutting because of their different thermal conductivities and reflectivities.

2.Material thickness

In addition, the thickness of the material will also affect the ability of the laser to penetrate. Thicker materials require higher laser power or adjustment of the cutting speed and focus position.

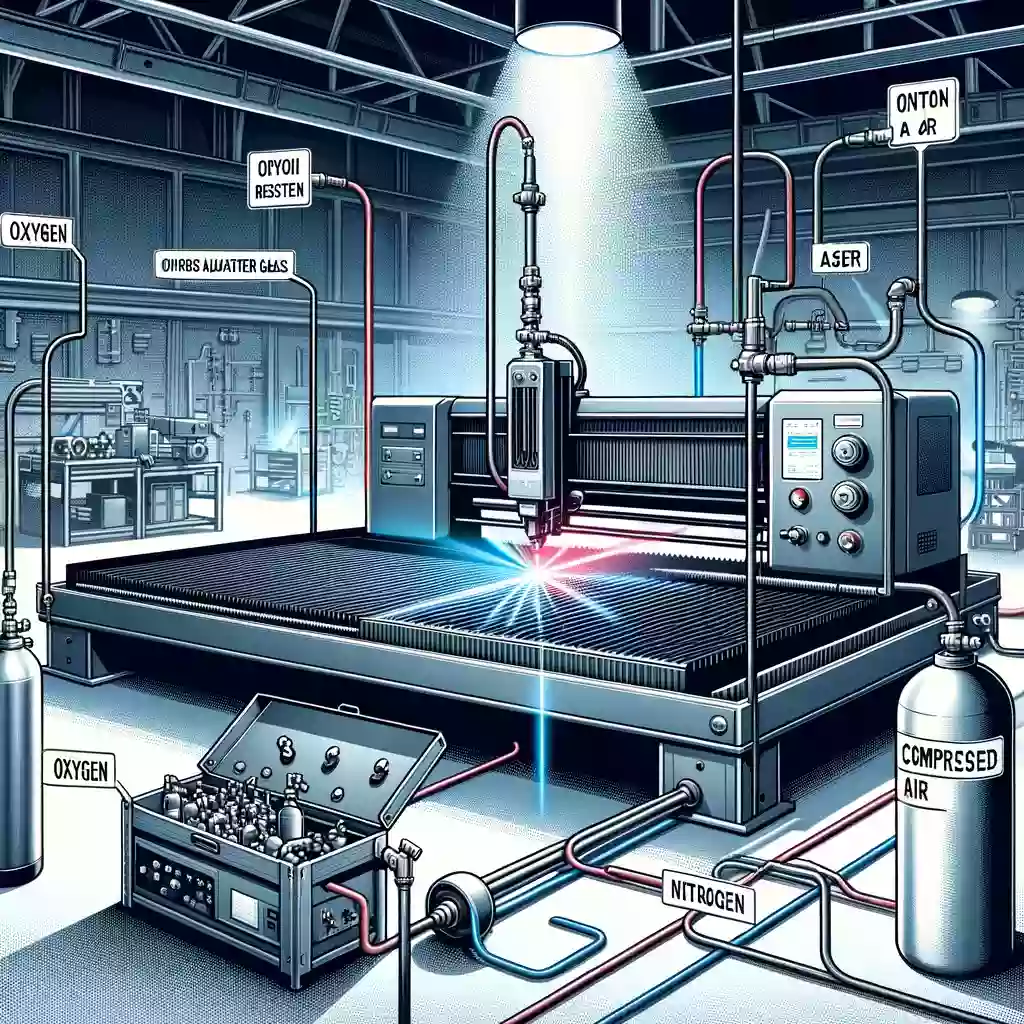

Ⅶ. Auxiliary Gas

1.Oxygen and nitrogen

During the laser cutting process, auxiliary gases such as oxygen, nitrogen or compressed air are usually used. Oxygen can support combustion and speed up the cutting process, but may leave oxidized edges; nitrogen cutting can maintain the smoothness of the metal and is suitable for cutting high-demand decorative materials.

2.Advantages of auxiliary gas

The auxiliary gas helps blow away the slag produced during the cutting process, while cooling the cutting area to prevent material burns. Different gases have different effects on the cutting effect. For example, oxygen can increase the cutting speed, while nitrogen can keep the cutting edge clean and smooth.

Ⅷ. Operational Technology

The skill level of the laser cutting machine operator is also an important factor. Skilled operation can ensure the accurate setting of laser cutting parameters, effectively avoid errors in operation, thereby improving cutting accuracy and efficiency.

Final Thoughts

All in all, laser cutting is a complex technology and its cutting quality is affected by many factors. Only by comprehensively understanding and properly controlling these factors can we effectively improve cutting efficiency and quality. With the continuous advancement of technology, laser cutting technology will be more intelligent and precise in the future, bringing convenience to more industries.